Aṣa tabi boṣewa irin alagbara, irin 316 camlock nipasẹilana simẹnti idokoati CNC ẹrọ.

Irin alagbara, irin ni akoonu chromium ti o kere ju ti 10.5%, ti o jẹ ki o ni sooro diẹ si awọn agbegbe omi bibajẹ ati si ifoyina. Sibẹsibẹ, eyi kii ṣe pipe. Awọn simẹnti idoko-owo irin alagbara jẹ “sooro ipata” nigba lilo ni awọn agbegbe omi ati awọn vapors ni isalẹ 1200°F (650°C) ati “sooro ooru” nigba lilo loke iwọn otutu yii. AISI 316 jẹ irin alagbara austenitic eyiti o jẹ lilo pupọ fun awọn simẹnti idoko-owo.

Irin alagbara, irin Austenitic yẹ ki o jẹ itọju to lagbara-ojutu ṣaaju lilo, nitorinaa lati mu iwọn ojutu to lagbara ti ọpọlọpọ awọn precipitates bii carbides ninu irin sinu matrix austenite, lakoko ti o tun ṣe isokan ti eto ati imukuro aapọn, nitorinaa lati rii daju pe o tayọ resistance resistance ati darí-ini. Eto itọju ojutu ti o tọ jẹ itutu agba omi lẹhin alapapo ni 1050 ~ 1150 ℃ (awọn ẹya tinrin tun le tutu afẹfẹ). Iwọn otutu itọju ojutu da lori iwọn alloying ti irin: Molybdenum-free tabi kekere-molybdenum irin onipò yẹ ki o wa ni isalẹ (≤1100℃), ati awọn ti o ga alloyed onipò bi 00Cr20Ni18Mo-6CuN, 00Cr25Ni22Mo2N, ati be be lo yẹ ki o jẹ ti o ga (. 1080~1150) ℃).

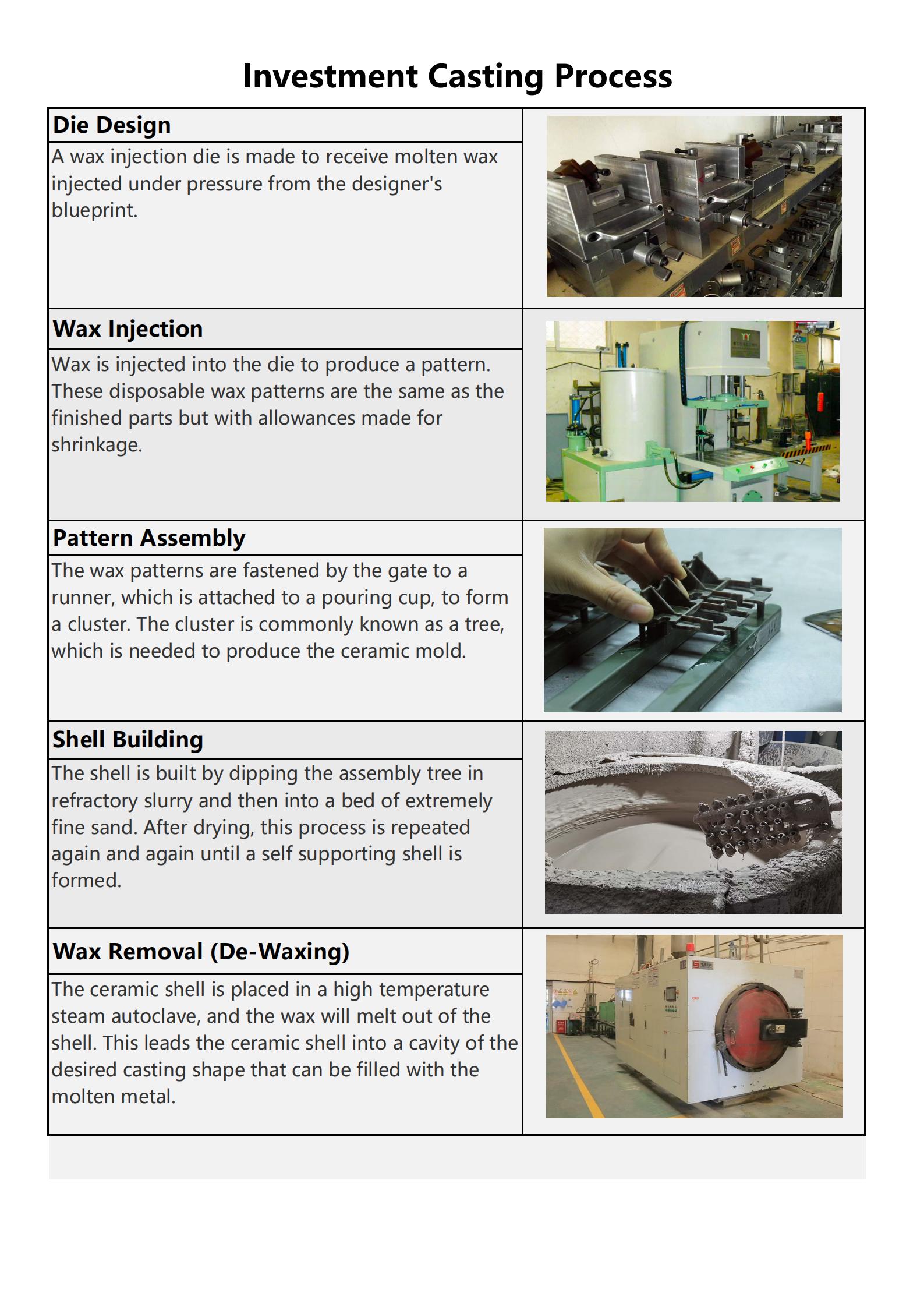

Awọn agbara ti Ipilẹ Simẹnti Idoko-owo:

- • Iwọn ti o pọju: 1,000 mm × 800 mm × 500 mm

- • Iwọn Iwọn: 0,5 kg - 100 kg

- • Agbara Ọdọọdun: 2,000 toonu

- • Awọn ohun elo iwe adehun fun Ilé Ikarahun: Silica Sol, Gilasi Omi ati awọn apopọ wọn.

- • Awọn ifarada: Lori Ibere.

Awọn anfani ti Awọn Irinṣe Simẹnti Idoko-owo:

- - O tayọ ati ki o dan dada pari

- - Ju onisẹpo tolerances.

- - eka ati intricate ni nitobi pẹlu oniru ni irọrun

- - Agbara lati sọ awọn odi tinrin nitorina paati simẹnti fẹẹrẹfẹ

- - Aṣayan nla ti awọn irin simẹnti ati awọn alloy (irin ati ti kii ṣe irin)

- - Akọpamọ ko nilo ni apẹrẹ awọn apẹrẹ.

- - Din awọn nilo fun Atẹle machining.

- - Kekere ohun elo egbin.

| Awọn ohun elo funSimẹnti idoko-owoIlana ni RMC Foundry | |||

| Ẹka | China ite | US ite | Germany ite |

| Ferritic Irin Alagbara | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Irin Alagbara | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic alagbara, irin | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4404, 8.9. 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Ojoriro Lile Alagbara Irin | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Ile oloke meji Irin alagbara | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| Giga Mn Irin | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Irin Irin | K12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Ooru Resistant Irin | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-mimọ Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOY600, INCOY625 | 2.4815, 2.4879, 2.4680 | |

| Aluminiomu Alloy | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Ejò Alloy | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Koluboti-mimọ Alloy | UMC50, 670, ite 31 | 2.4778 | |

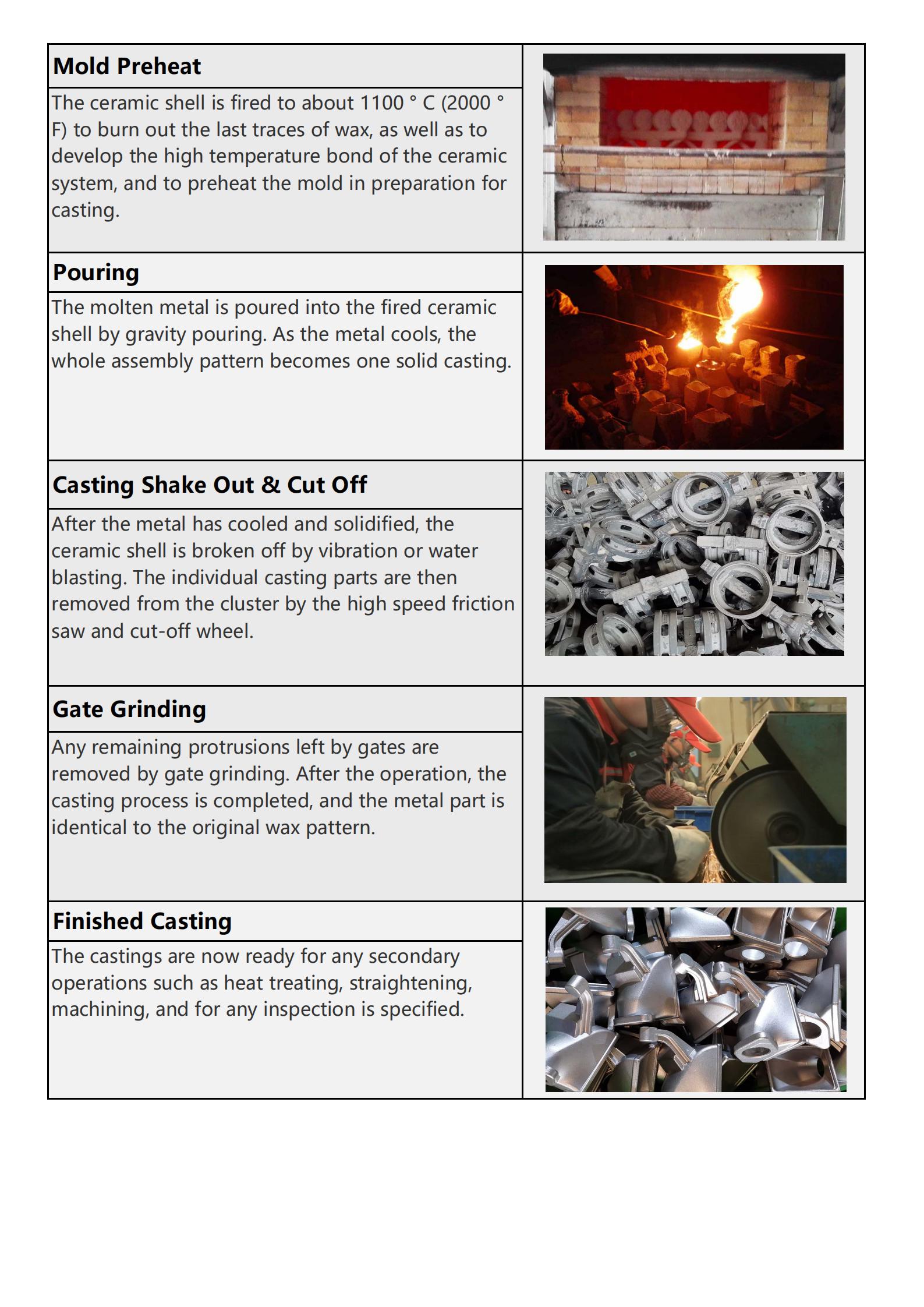

| IFỌRỌWỌRỌ SIMỌ IDODO | |||

| Inṣi | Milimita | ||

| Iwọn | Ifarada | Iwọn | Ifarada |

| Titi di 0.500 | ±.004" | Titi di 12.0 | ± 0.10mm |

| 0.500 si 1.000” | ±.006" | 12.0 to 25.0 | ± 0.15mm |

| 1.000 si 1.500” | ±.008" | 25.0 to 37.0 | ± 0.20mm |

| 1.500 si 2.000” | ±.010" | 37.0 to 50.0 | ± 0.25mm |

| 2.000 si 2.500” | ±.012" | 50.0 to 62.0 | ± 0.30mm |

| 2.500 si 3.500” | ±.014" | 62.0 to 87.0 | ± 0.35mm |

| 3.500 si 5.000” | ±.017" | 87.0 to 125.0 | ± 0.40mm |

| 5.000 si 7.500” | ±.020" | 125.0 to190.0 | ± 0.50mm |

| 7.500 si 10.000” | ±.022" | 190.0 to 250.0 | ± 0.57mm |

| 10.000 si 12.500” | ±.025" | 250.0 to 312.0 | ± 0.60mm |

| 12.500 to 15.000 | ±.028" | 312.0 to 375.0 | ± 0.70mm |