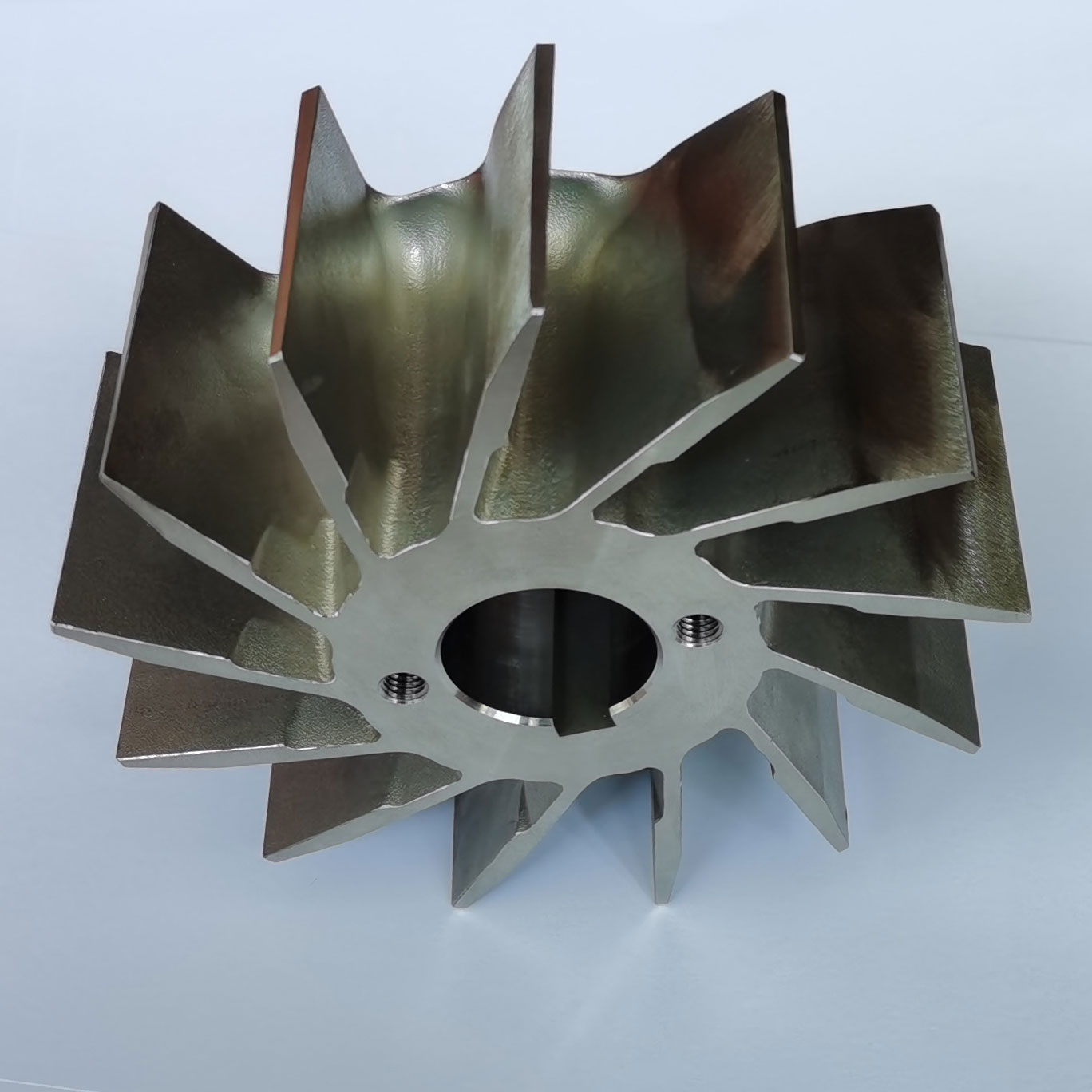

CF8M Simẹnti alagbara, irin ìmọ impeller fun centrifugal fifa nipasẹ idoko simẹnti,CNC ẹrọati iwontunwosi ìmúdàgba.

CF8M jẹ irin alagbara simẹnti austenitic ti o ni aabo nipasẹ ASTM A351, ASTM A743 ati ASTM A744 boṣewa. CF8M dogba si SS 316/F 316 ati Chinese Standard 0Cr17Ni12Mo2. CF8M jẹ iyipada ti nru molybdenum ti CF8 alloy ati pe o jẹ simẹnti deede ti AISI 316 Irin alagbara ti a ṣe. Iwaju molybdenum ṣe alekun resistance ipata gbogbogbo ati resistance si pitting nipasẹ awọn chlorides. A lo alloy ni awọn ipo ekikan kekere ati ipilẹ ati fun mimu citric, oxalic ati phosphoric acids. Irin alagbara, irin CF8M jẹ okeene kanna bi SS 316, F 316 ati TP 316. Sugbon ti won ti wa ni telẹ ni orisirisi awọn ajohunše, ati awọn won kemikali ati darí ini ni o wa kekere kan yatọ si tun. CF8M jẹ asọye ni ASMT A351, ASMT A743 ati ASTM A744, eyiti o jẹ fun idi simẹnti nikan. SS 316 jẹ asọye ni ASTM A240 ati ASTM A276, o jẹ fun awo, dì, rinhoho tabi awọn ọpa irin alagbara. Ipele miiran jẹ oniwa bi F316, eyiti o wa lati ASTM A182 fun awọn ẹya ti o ni iro nikan. TP316 yoo wa ni ATSTM A376 fun paipu nikan. Awọn ohun elo akọkọ ti CF8M simẹnti irin alagbara, irin ideri: impellors, propellers, fifa casings, àtọwọdá ara ati tẹ awo. Itọju igbona igbagbogbo fun CF8M jẹ Solusan to lagbara nipasẹ alapapo si diẹ sii ju 1900 °F (1040 °C), dani fun akoko ti o to ati lẹhinna pa ninu omi tabi itutu ni iyara nipasẹ awọn ọna miiran.

| Data Imọ-ẹrọ Simẹnti idoko-owo ni RMC | |

| R&D | Software: Solidworks, CAD, Procast, Pro-e |

| Akoko asiwaju fun Idagbasoke ati Awọn ayẹwo: 25 si 35 ọjọ | |

| Didà Irin | Irin Alagbara Ferritic, Irin Alagbara Martensitic,Austenitic alagbara, irin, Ojoriro Hardening Alagbara Irin, Duplex alagbara, irin |

| Irin Erogba, Irin Alloy, Irin Irinṣẹ, Irin Resistant Ooru, | |

| Nickle-base Alloy, Aluminium Alloy, Copper-base Alloy, Cobalt-base Alloy | |

| Irin Standard | ISO, GB, ASTM, SAE, GOST EN, DIN, JIS, BS |

| Ohun elo fun Ikarahun Ilé | Silica Sol (Silica ti o ṣaju) |

| Gilasi Omi (Silicate sodium) | |

| Awọn apopọ ti Silica Sol ati Gilasi Omi | |

| Imọ paramita | Iwọn Nkan: 2 giramu si 200 kilo giramu |

| Iwọn ti o pọju: 1,000 mm fun Opin tabi Gigun | |

| Min Odi Sisanra: 1.5mm | |

| Simẹnti Roughness: Ra 3.2-6.4, Ṣiṣẹda Roughness: Ra 1.6 | |

| Ifarada ti Simẹnti: VDG P690, D1/CT5-7 | |

| Ifarada ti ẹrọ: ISO 2768-mk / IT6 | |

| Inu Inu: Seramiki Core, Urea Core, Water Soluble Wax Core | |

| Ooru Itoju | Deede, Tempering, Quenching, Annealing, Solusan, Carburization. |

| dada Itoju | Didan, Iyanrin/Iru arugbo, Pipa Zinc, Pipọ nickel, Itọju Oxidation, Fosfating, Kikun lulú, Geormet, Anodizing |

| Idanwo Dimension | CMM, Vernier Caliper, Inu Caliper. Gage Ijinle, Giga Gage, Lọ/Ko lọ Gage, Awọn imuduro pataki |

| Ayẹwo Kemikali | Itupalẹ Iṣapọ Kemikali (awọn eroja kẹmika 20), Ayewo mimọ, Ayẹwo redio X-ray, Oluyanju erogba-sulfur |

| Ayẹwo ti ara | Iwontunwonsi Yiyi, Blancing Aimi, Awọn Ohun-ini Mechanical (Lile, Agbara Ikore, Agbara Fifẹ), Ilọsiwaju |

| Agbara iṣelọpọ | Diẹ sii ju awọn toonu 250 fun oṣu kan, diẹ sii ju awọn toonu 3,000 lọdọọdun. |

Iṣapọ Kemikali ti Irin Alagbara Simẹnti CF8M:

Erogba: 0.08 max

Manganese: 1.50 max

Ohun alumọni: 1,50 max

Efin: 0.040 max

Fọsifọọsi: 0.040 max

Chromium: 18.0-21.0

Nickel: 9.0-12.0

Molybdenum: 2.0-3.0

Awọn ohun-ini Mekaniki ti Irin Alagbara Simẹnti CF8M:

Agbara Fifẹ: min 70 ksi (485 Mpa)

Agbara Ikore: min 30 ksi (205 Mpa)

Elongation ni 2 inch. tabi 50 mm: min 30.0%

Kini idi ti a pe wọn ni CF8M?

Gẹgẹbi yiyan, lẹta akọkọ C tumọ si iṣẹ ti o pinnu lati lo ninu iṣẹ sooro ipata, ṣugbọn nigbami o tumọ si lilo CASTING nitori iwọ yoo rii F 316 ni ASTM A 350 (F = FORGE). Lẹta keji F tọkasi ipo isunmọ ti alloy lori aworan atọka irin-chromium-nickel (FeCrNi). Fun awọn olumulo ti o faramọ pẹlu aworan atọka, lẹta keji n pese itọkasi ti irin, nickel, ati akoonu chromium, ṣugbọn ọpọlọpọ eniyan yoo ni lati gba alaye alloying lati sipesifikesonu ohun elo kan. Awọn lẹta kẹta ati ẹkẹrin 8M ṣe afihan akoonu erogba idasilẹ ti o pọju ni awọn iwọn 0.01% (fun apẹẹrẹ, CF8M ni o pọju 0.08% erogba)