CNC konge ẹrọ idẹ awọn ọja nipasẹ sisọnu idoko-idoko epo-eti, itọju ooru ati itọju dada gẹgẹbi awọn iyaworan imọ-ẹrọ rẹ ati awọn ibeere alailẹgbẹ.

CNC ẹrọtọka si ilana ṣiṣe ẹrọ ti o tẹsiwaju nipasẹ Iṣakoso Nọmba Kọmputa (CNC fun kukuru). O jẹ iranlọwọ nipasẹ CNC lati de ipo giga ati iduroṣinṣin pẹlu idiyele iṣẹ ti o dinku. Machining jẹ eyikeyi awọn ilana lọpọlọpọ ninu eyiti a ge nkan ti ohun elo aise sinu apẹrẹ ipari ti o fẹ ati iwọn nipasẹ ilana imukuro ohun elo ti iṣakoso. Awọn ilana ti o ni koko-ọrọ ti o wọpọ, yiyọ ohun elo iṣakoso, ni a mọ loni ni apapọ bi iṣelọpọ iyokuro, ni iyatọ si awọn ilana ti afikun ohun elo iṣakoso, eyiti a mọ si iṣelọpọ aropo.

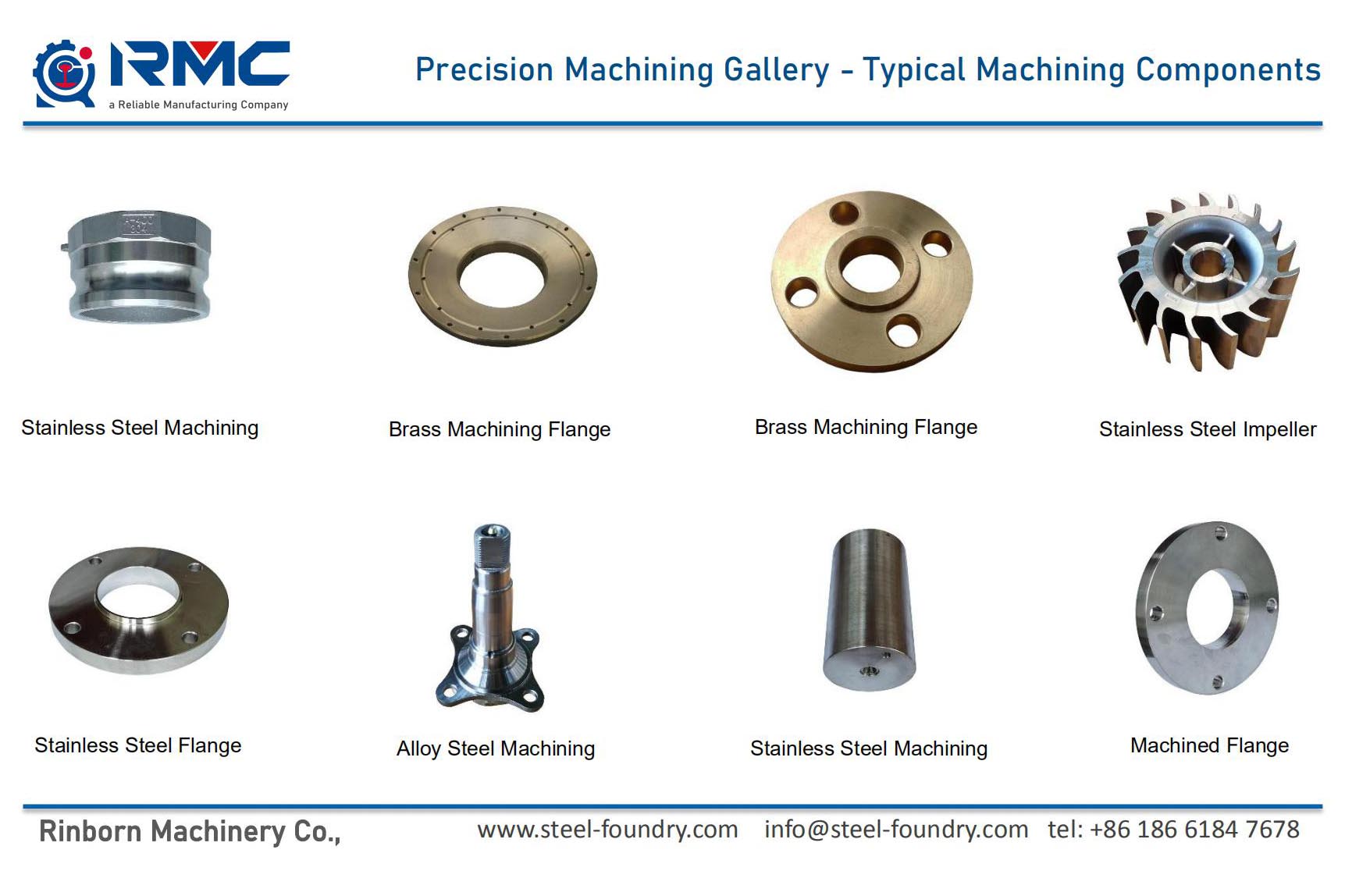

Gangan ohun ti apakan “iṣakoso” ti asọye tumọ si le yatọ, ṣugbọn o fẹrẹ jẹ nigbagbogbo tumọ si lilo awọn irinṣẹ ẹrọ (ni afikun si awọn irinṣẹ agbara ati awọn irinṣẹ ọwọ). Eyi jẹ ilana ti a lo lati ṣe ọpọlọpọirin ẹrọ awọn ọja, ṣugbọn o tun le ṣee lo lori awọn ohun elo gẹgẹbi igi, ṣiṣu, seramiki, ati awọn akojọpọ. Awọn ẹrọ CNC ni wiwa ọpọlọpọ awọn ilana ti o yatọ gẹgẹbi milling, titan, lathing, liluho, honing, lilọ ... ati be be lo.

Idẹ jẹ ti awọnEjò-orisun alloyati ki o jẹ ẹya alloy kq Ejò ati sinkii. Idẹ kq ti bàbà ati sinkii ni a npe ni arinrin idẹ. Ti o ba jẹ orisirisi awọn alloy ti o ni awọn eroja ti o ju meji lọ, a npe ni idẹ pataki. Idẹ jẹ alloy Ejò pẹlu sinkii bi eroja akọkọ. Bi akoonu zinc ṣe pọ si, agbara ati ṣiṣu ti alloy pọ si ni pataki, ṣugbọn awọn ohun-ini ẹrọ yoo dinku ni pataki lẹhin ti o kọja 47%, nitorinaa akoonu zinc ti idẹ kere ju 47%. Ni afikun si zinc, idẹ simẹnti nigbagbogbo ni awọn eroja alloying gẹgẹbi silikoni, manganese, aluminiomu, ati asiwaju.

| CNC konge Machining Agbara | ||||

| Awọn ohun elo | Opoiye | Iwọn Iwọn | Lododun Agbara | Gbogbogbo Yiye |

| Ile-iṣẹ Ṣiṣepo inaro (VMC) | 48 ṣeto | 1500mm × 1000mm × 800mm | 6000 tonnu tabi 300000 awọn ege | ± 0.005 |

| Petele ile-iṣẹ ẹrọ (VMC) | 12 ṣeto | 1200mm × 800mm × 600mm | 2000 toonu tabi 100000 awọn ege | ± 0.005 |

| Ẹrọ CNC | 60 ṣeto | Iwọn iyipada ti o pọju. φ600mm | 5000 toonu tabi 600000 awọn ege | |

| Standard Excutive of Simẹnti Ifarada: ISO 8062 2013, ISO 2768, GOST 26645 (Russia) tabi GBT 6414 (China). | ||||

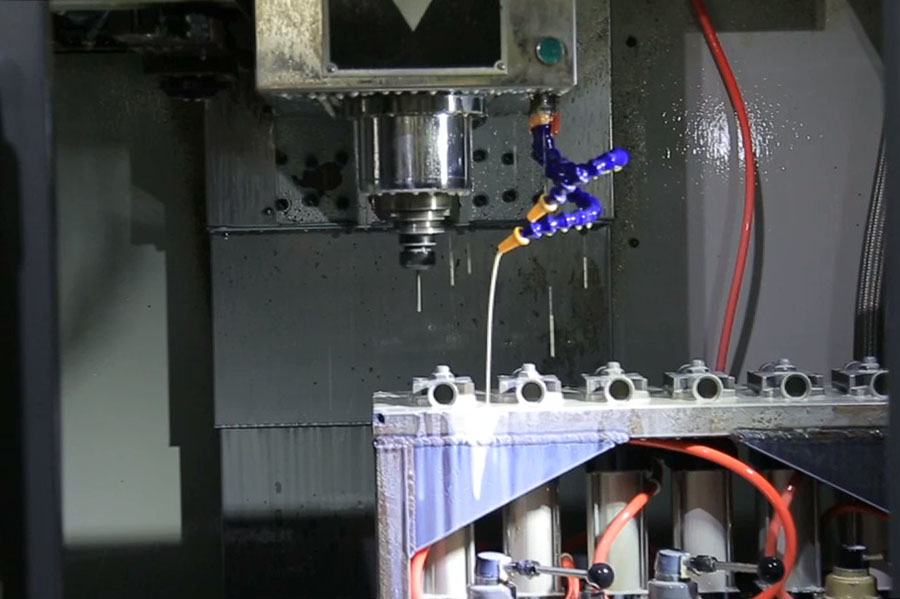

Ile-iṣẹ ẹrọ ti wa ni idagbasoke lati ẹrọ milling CNC. Iyatọ nla julọ lati ẹrọ milling CNC ni pe ile-iṣẹ ẹrọ ni agbara lati ṣe paṣipaarọ awọn irinṣẹ ẹrọ laifọwọyi. Nipa fifi awọn irinṣẹ sori ẹrọ fun awọn idi oriṣiriṣi lori iwe irohin ọpa, awọn irinṣẹ ẹrọ ti o wa lori spindle le yipada nipasẹ oluyipada irinṣẹ laifọwọyi ni didi kan lati mọ awọn ẹya ẹrọ ẹrọ pupọ.

Ile-iṣẹ ẹrọ CNC jẹ ohun elo ẹrọ adaṣe adaṣe ti o ga julọ ti o jẹ ohun elo ẹrọ ati eto CNC ati pe o dara fun sisẹ awọn ẹya eka. Ile-iṣẹ ẹrọ CNC jẹ lọwọlọwọ ọkan ninu awọn irinṣẹ ẹrọ CNC ti o lo pupọ julọ ni agbaye pẹlu agbara sisẹ okeerẹ to lagbara. O le pari akoonu sisẹ diẹ sii lẹhin ti iṣẹ-ṣiṣe ti dina ni akoko kan. Awọn išedede processing jẹ ga. Fun awọn iṣẹ ṣiṣe ipele pẹlu iṣoro sisẹ alabọde, ṣiṣe rẹ jẹ awọn akoko 5-10 ti ohun elo lasan, ni pataki o le pari Ọpọlọpọ awọn ilana ti ko le pari nipasẹ ohun elo lasan jẹ dara julọ fun sisẹ nkan-ẹyọkan pẹlu awọn nitobi eka diẹ sii ati awọn ibeere konge giga tabi fun kekere ati alabọde ipele gbóògì ti ọpọ awọn orisirisi. O ṣojumọ awọn iṣẹ ti ọlọ, alaidun, liluho, titẹ ati gige awọn okun lori ẹrọ kan, ki o ni ọpọlọpọ awọn ọna imọ-ẹrọ.

| Ifiwera Ite ti Ejò, Idẹ ati Idẹ | |||||||

| EGBE | AISI | W-stoff | DIN | BS | JIS | EN | ISO |

| Idẹ | C10200 | 2.0040 | TI Ku | C103 | C1020 | CW008A | Cu-OF |

| C11000 | 2.0060 | E-Cu57 | C101 | C1100 | CW004A | Cu-ETP | |

| - | 2.0065 | E-Cu58 | - | - | - | - | |

| C10300 | 2.0070 | SE Ku | - | - | CW021A | - | |

| C12200 | 2.0090 | SF KU | C106 | C1220 | CW024A | Cu-DHP | |

| C12500 | - | Cu-FRTP | C104 | - | CR006A | - | |

| C70320 | 2.0857 | - | - | - | CW112C | CuNi3Si | |

| C14200 | 2.1202 | SB Ku | C107 | - | - | Cu-AsP | |

| - | 2.1356 | Ku Mn 3 | - | - | - | - | |

| - | 2.1522 | Cu Si2 Mn | - | - | - | - | |

| C16200 | - | C108 | - | - | CuCd1 | ||

| C18200 | - | CC101 | - | CW105C | CuCr1 | ||

| C191010 | - | - | - | CW109C | CuNi1Si | ||

| C70250 | - | CC102 | - | CW111C | CuNi2Si | ||

| C17200 | - | CB101 | - | CW101C | CuBe2 | ||

| C17300 | - | - | - | CW102C | CuBe2Pb | ||

| C17510 | - | - | - | CW110C | CuNi2Be | ||

| C17500 | - | C112 | - | CW104C | CuCo2Be | ||

| C15000 | - | - | - | CW120C | CuZr | ||

| C65100 | - | - | - | CW115C | CuSi2Mn | ||

| C65500 | - | CS101 | - | CW116C | CuSi3Mn1 | ||

| C14500 | - | C109 | - | CW118C | CuTeP | ||

| C14700 | - | C111 | - | CW114C | CuSP | ||

| C18700 | - | - | - | CW113C | Cupb1P | ||

| BRASS | C21000 | 2.0220 | CuZn5 | CZ125 | C2100 | CW500L | - |

| C22000 | 2.0230 | CuZn10 | Cz101 | C2200 | CW501L | - | |

| C23000 | 2.0240 | CuZn15 | CZ102 | C2300 | CW502L | - | |

| C24000 | 2.0250 | CuZn20 | CZ103 | C2400 | CW503L | - | |

| C25600 | - | CuZn28 | - | - | - | - | |

| C26000 | 2.0265 | CuZn30 | CZ106 | C2600 | CW505L | - | |

| C26800 | 2.0280 | CuZn33 | - | C2680 | CW506L | - | |

| C27200 | - | CuZn36 | - | - | - | - | |

| C27200 | 2.0321 | CuZn37 | CZ108 | C2700 | CW508L | - | |

| C27000 | 2.0335 | CuZn36 | CZ107 | C2700 | CW507L | - | |

| C28000 | 2.0360 | CuZn40 | CZ109 | C2800 | CW509L | - | |

| C33500 | - | CuZn37Pb0.5 | - | - | - | - | |

| C34000 | - | CuZn35Pb1 | CZ118 | C3501 | - | - | |

| C34500 | 2.0331 | CuZn36Pb1,5 | CZ119 | - | CW601N | - | |

| C34000 | 2.0331 | CuZn36Pb1,5 | CZ119 | C3501 | CW600N | - | |

| C35300 | 2.0371 | CuZn38Pb1,5 | CZ128 | - | - | - | |

| C36500 | 2.0372 | CuZn39Pb0,5 | CZ123 | - | CW610N | - | |

| C36000 | 2.0375 | CuZn36Pb3 | CZ124 | C3601 | CW603N | - | |

| C37700 | 2.0380 | CuZn39Pb2 | CZ 131 / (CZ128) | C3771 | CW612N | - | |

| C38500 | 2.0401 | CuZn39Pb3 | CZ121 | C3603 | CW614N | - | |

| C38000 | 2.0402 | CuZn40Pb2 | CZ122 | - | CW617N | - | |

| - | 2.0410 | CuZn44Pb2 | CZ130 | - | - | - | |

| C68700 | 2.0460 | CuZn20Al2 | CZ110 | - | - | - | |

| C44300 | 2.0470 | CuZn28Sn1 | CZ111 | - | - | - | |

| - | 2.0530 | CuZn38Sn1 | - | - | - | - | |

| - | 2.0550 | CuZn40Al2 | - | - | - | - | |

| - | 2.0561 | CuZn40Al1 | - | - | - | - | |

| - | 2.0572 | CuZn40Mn2 | CZ136 | - | CW723R | - | |

| C61400 | 2.0932 | CuAl8Fe3 | - | - | CW303G | - | |

| C63000 | 2.0966 | CuAl10Ni5Fe4 | CA104 | - | CW307G | - | |

| Idẹ | C50700 | 2.1010 | CuSn2 | - | - | - | - |

| C51100 | 2.1016 | CuSn4 | PB101 | C5111 | CW450K | - | |

| C51000 | - | CuSn5 | PB102 | C5102 | CW451K | - | |

| C51900 | 2.1020 | CuSn6 | PB103 | C5191 | CW452K | - | |

| C52100 | 2.1030 | CuSn8 | PB104 | C5212 | CW453K | - | |

| - | - | CuSn10 | - | - | - | - | |

| - | - | CUSn11 | - | - | - | - | |

| - | - | CuSn12 | - | - | - | - | |

Awọn ile-iṣẹ ẹrọ ti wa ni ipin si petele ati awọn ile-iṣẹ ẹrọ inaro ni ibamu si ipo aye wọn lakoko ṣiṣe ẹrọ spindle. Ni ipin ni ibamu si lilo ilana: alaidun ati ile-iṣẹ ẹrọ milling, ile-iṣẹ iṣelọpọ agbo. Ni ibamu si awọn pataki classification ti awọn iṣẹ, nibẹ ni o wa: nikan workbench, ė workbench ati olona-workbench machining aarin. Awọn ile-iṣẹ ẹrọ pẹlu ẹyọkan-apa, meji-axis, mẹta-axis, mẹrin-axis, marun-axis ati interchangeable headstocks, etc.

CNC machining jẹ iru ẹrọ ṣiṣe deede nipasẹ awọn ẹrọ CNC gẹgẹbi awọn ile-iṣẹ iṣelọpọ ti ilọsiwaju ti o ni opin oke 5 axis machining center, 4 axis double platform machining center, tabi CNC titan lathes eyiti o tun le ni idagbasoke si ile-iṣẹ titan CNC ti o ni agbara ti iyipada diẹ sii. ju 15 cutters laarin ọkan dani naficula; CNC milling ẹrọ ati CNC liluho ati kia kia awọn ile-iṣẹ. Ṣiṣe deedee ti simẹnti irin yatọ si sisẹ profaili irin. Simẹnti pipe ti ṣaṣeyọri apẹrẹ gangan ti ohun ti o fẹ, nitorinaa o ṣafipamọ ọpọlọpọ ẹrọ ni akawe pẹlu ẹrọ lati profaili irin taara. Paapaa nitori idi eyi, a nigbagbogbo ni lati gbero oju ẹrọ ẹrọ ati iyọọda ẹrọ to dara ṣaaju simẹnti. Ohun elo wa deede ni lati ṣiṣẹ iyaworan simẹnti aise pẹlu iyaworan ẹrọ lati pato agbegbe ẹrọ ati iyọọda ẹrọ lori iyaworan naa.

Ipilẹ simẹnti idoko-owo RMC ti ni ipese pẹlu awọn ile-iṣẹ machining axis 4, awọn eto 15 ti awọn lathes titan CNC ati awọn eto 3 ti awọn ẹrọ milling cnc, pẹlu iranlọwọ titan titan ti o wọpọ ti o wọpọ, milling, titẹ ni kia kia, liluho ati awọn ẹrọ lilọ, a ni agbara ti machining fere gbogbo iru irin simẹnti.

Tun npe ni machining konge, awọn CNC machining le de ọdọ kan gan ga yiye ni ifarada jiometirika ati onisẹpo ifarada. Pẹlu awọn ẹrọ CNC wa ati Awọn ile-iṣẹ Iṣeduro Horizontal (HMC) ati Awọn ile-iṣẹ Iṣeduro inaro (VMC), a le fẹrẹ pade gbogbo awọn iwọn ifarada ti o nilo.

Awọn agbara tiIdoko Simẹnti Foundry:

• Iwọn ti o pọju: 1,000 mm × 800 mm × 500 mm

• Iwọn Iwọn: 0,5 kg - 100 kg

• Agbara Ọdọọdun: 2,000 toonu

• Awọn ohun elo iwe adehun fun Ilé Ikarahun: Silica Sol, Gilasi Omi ati awọn apopọ wọn.

• Awọn ifarada: Lori Ibere.

Awọn anfani tiIdoko Simẹnti irinše:

- O tayọ ati ki o dan dada pari

- Ju onisẹpo tolerances.

- eka ati intricate ni nitobi pẹlu oniru ni irọrun

- Agbara lati sọ awọn odi tinrin nitorina paati simẹnti fẹẹrẹfẹ

- Aṣayan nla ti awọn irin simẹnti ati awọn alloy (irin ati ti kii ṣe irin)

- Akọpamọ ko nilo ni apẹrẹ awọn apẹrẹ.

- Din awọn nilo fun Atẹle machining.

- Kekere ohun elo egbin.

| IFỌRỌWỌRỌ SIMỌ IDODO | |||

| Inṣi | Milimita | ||

| Iwọn | Ifarada | Iwọn | Ifarada |

| Titi di 0.500 | ±.004" | Titi di 12.0 | ± 0.10mm |

| 0.500 si 1.000” | ±.006" | 12.0 to 25.0 | ± 0.15mm |

| 1.000 si 1.500” | ±.008" | 25.0 to 37.0 | ± 0.20mm |

| 1.500 si 2.000” | ±.010" | 37.0 to 50.0 | ± 0.25mm |

| 2.000 si 2.500” | ±.012" | 50.0 to 62.0 | ± 0.30mm |

| 2.500 si 3.500” | ±.014" | 62.0 to 87.0 | ± 0.35mm |

| 3.500 si 5.000” | ±.017" | 87.0 to 125.0 | ± 0.40mm |

| 5.000 si 7.500” | ±.020" | 125.0 to190.0 | ± 0.50mm |

| 7.500 si 10.000” | ±.022" | 190.0 to 250.0 | ± 0.57mm |

| 10.000 si 12.500” | ±.025" | 250.0 to 312.0 | ± 0.60mm |

| 12.500 to 15.000 | ±.028" | 312.0 to 375.0 | ± 0.70mm |