Irin simẹnti ti ko ni ipata, ti a tun pe ni simẹnti irin alagbara, n tọka si irin simẹnti alloy ti o ṣe afihan resistance to lagbara si ipata ni ọpọlọpọ awọn media ipata pato tabi agbegbe nibiti ipata ati awọn ifosiwewe ẹrọ n gbe papọ.

| Awọn iwo iyara fun Irin Alagbara Austenitic | |

| Ifilelẹ Kemikali akọkọ | Cr,Ni,C,Mo,Cu,Si,Nb,Ti |

| Iṣẹ ṣiṣe | Ti kii ṣe oofa, lile giga, ṣiṣu giga, agbara kekere |

| Itumọ | Irin alagbara, irin pẹlu austenitic be ni yara otutu |

| Awọn giredi Aṣoju | 304, 316, 1.4310, 1.4301, 1.4408 |

| Ṣiṣe ẹrọ | Otitọ |

| Weldability | Ni gbogbogbo dara pupọ |

| Awọn Lilo Aṣoju | Awọn ẹrọ ounjẹ, Awọn ohun elo, Ṣiṣẹpọ Kemikali ... ati bẹbẹ lọ |

Irin alagbara, irin ni akoonu chromium ti o kere ju ti 10.5%, ti o jẹ ki o ni sooro diẹ si awọn agbegbe omi bibajẹ ati si ifoyina. O jẹ sooro ipata pupọ ati sooro, pese ẹrọ ti o dara julọ, ati pe o jẹ olokiki daradara fun irisi ẹwa rẹ. Awọn simẹnti idoko-owo irin alagbara jẹ “sooro ipata” nigba lilo ni awọn agbegbe omi ati awọn vapors ni isalẹ 1200°F (650°C) ati “sooro ooru” nigba lilo loke iwọn otutu yii.

Austenitic alagbara, irinntokasi si irin alagbara, irin pẹlu ohun austenitic be ni yara otutu. Irin alagbara Austenitic jẹ ọkan ninu awọn kilasi marun ti irin alagbara, irin nipasẹ ọna kika kirisita (pẹlu ferritic, martensitic, duplex ati ojoriro lile). Ni diẹ ninu awọn agbegbe, irin alagbara austtentite tun ni a npe ni 300 jara alagbara, irin. Nigbati irin ba ni nipa 18% Cr, 8% -25% Ni, ati nipa 0.1% C, o ni eto austenite iduroṣinṣin. Irin alagbara chromium-nickel Austenitic pẹlu irin olokiki 18Cr-8Ni irin ati irin giga Cr-Ni jara ti o dagbasoke nipasẹ fifi akoonu Cr ati Ni ati ṣafikun Mo, Cu, Si, Nb, Ti ati awọn eroja miiran lori ipilẹ yii. Irin alagbara Austenitic kii ṣe oofa ati pe o ni lile giga ati ṣiṣu, ṣugbọn agbara rẹ kere, ati pe ko ṣee ṣe lati fun u ni okun nipasẹ iyipada alakoso. O le ni okun nikan nipasẹ iṣẹ tutu. Ti awọn eroja bii S, Ca, Se, Te ba ṣafikun, o ni awọn ohun-ini to dara ti ẹrọ.

Irin alagbara Austenitic tun le gbe awọn simẹnti jade. Lati le ni ilọsiwaju ṣiṣan ti irin didà ati ilọsiwaju iṣẹ ṣiṣe simẹnti, ohun elo alloy ti irin simẹnti yẹ ki o ṣatunṣe nipasẹ jijẹ akoonu ohun alumọni, titobi iwọn chromium ati akoonu nickel, ati jijẹ opin oke ti sulfur ano aimọ.

Irin alagbara, irin Austenitic yẹ ki o jẹ itọju to lagbara-ojutu ṣaaju lilo, nitorinaa lati mu iwọn ojutu to lagbara ti ọpọlọpọ awọn precipitates bii carbides ninu irin sinu matrix austenite, lakoko ti o tun ṣe isokan ti eto ati imukuro aapọn, nitorinaa lati rii daju pe o tayọ resistance resistance ati darí-ini. Eto itọju ojutu ti o tọ jẹ itutu agba omi lẹhin alapapo ni 1050 ~ 1150 ℃ (awọn ẹya tinrin tun le tutu afẹfẹ). Iwọn otutu itọju ojutu da lori iwọn alloying ti irin: Molybdenum-free tabi kekere-molybdenum irin onipò yẹ ki o wa ni isalẹ (≤1100℃), ati awọn ti o ga alloyed onipò bi 00Cr20Ni18Mo-6CuN, 00Cr25Ni22Mo2N, ati be be lo yẹ ki o jẹ ti o ga (. 1080~1150) ℃).

Austenitic 304 irin alagbara, irin awo, eyi ti o ti wa ni wi lati mu lagbara egboogi-ipata ati ipata resistance, ati ki o ni o tayọ ṣiṣu ati toughness, eyi ti o jẹ rọrun fun stamping ati lara. Pẹlu iwuwo ti 7.93 g / cm3, irin alagbara 304 jẹ irin alagbara ti o wọpọ pupọ, ti a tun mọ ni 18/8 irin alagbara ni ile-iṣẹ naa. Awọn ọja irin rẹ jẹ sooro si awọn iwọn otutu giga ati ni awọn ohun-ini sisẹ to dara, nitorinaa wọn lo jakejado ni ile-iṣẹ ati awọn ile-iṣẹ ọṣọ ohun ọṣọ ati ounjẹ ati awọn ile-iṣẹ iṣoogun.

Ite deede ti Irin Alagbara | |||||||

| Awọn ẹka | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic ati Ferritic Irin Alagbara | 420 C | 1.4034 | X43Cr16 | ||||

| 440 B/1 | 1.4112 | X90 cr Mo V18 | |||||

| - | 1.2083 | X42 cr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 cr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | X12 CrS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 cr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 cr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Austenitic Irin Alagbara | 304 | 1.4301 | X5 KrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 KrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 KrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Ile oloke meji Irin alagbara | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

Irin ati Awọn ohun elo ti kii ṣe irin fun Simẹnti Idoko-owo, Ilana Simẹnti epo-eti ti sọnu:

- • Irin grẹy: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

- • Irin Ductile tabi Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

- • Erogba Irin: AISI 1020 - AISI 1060, C30, C40, C45.

- • Irin Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo ... ati be be lo lori ìbéèrè.

- • Irin alagbara: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 ati awọn miiran alagbara, irin ite.

- • Brass, Red Copper, Bronze tabi awọn irin alloy ti o da lori Ejò: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

- • Awọn ohun elo miiran gẹgẹbi awọn ibeere alailẹgbẹ rẹ tabi ni ibamu si ASTM, SAE, AISI, ACI, DIN, EN, ISO, ati awọn ajohunše GB

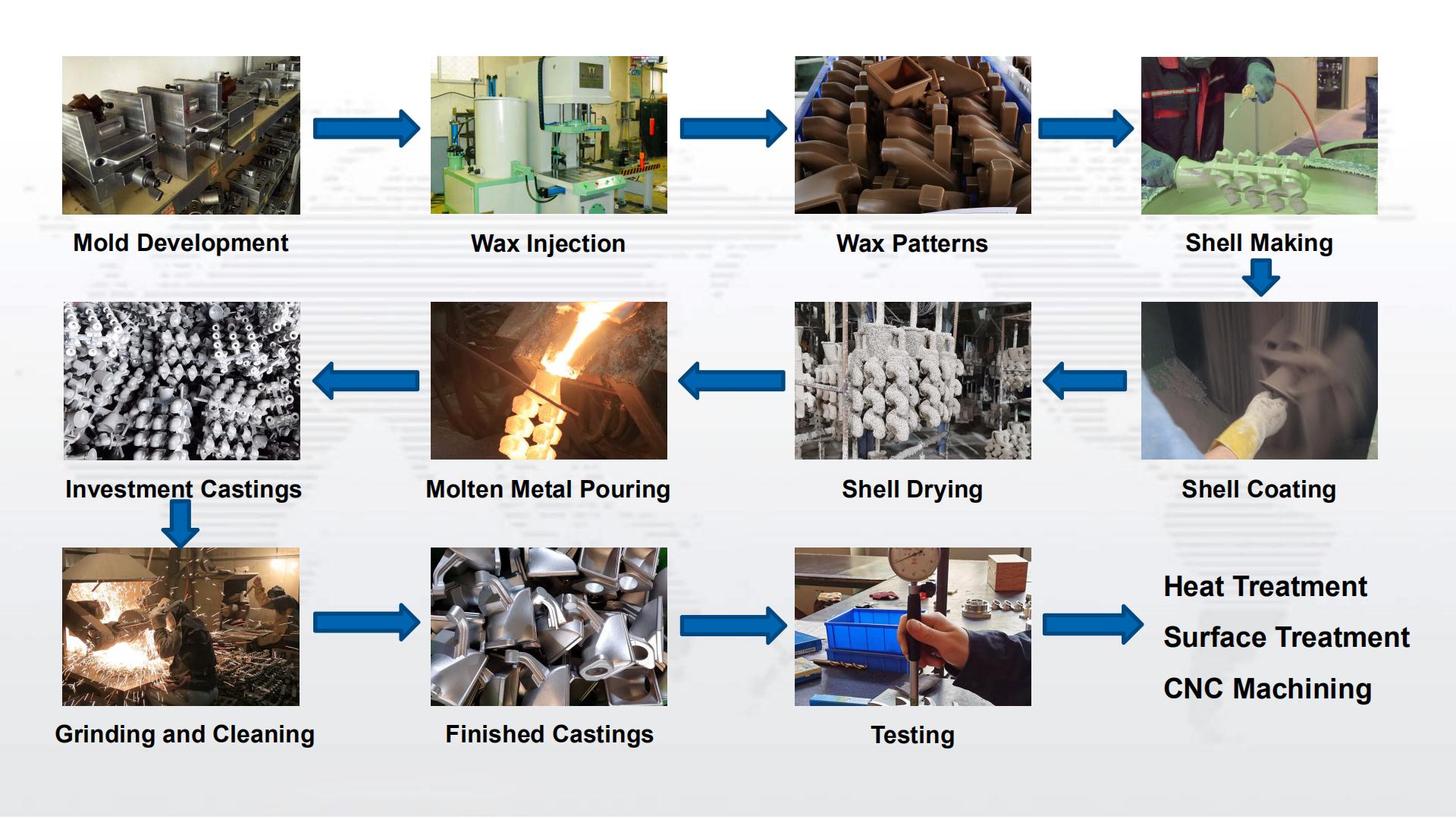

Awọn igbesẹ ti o kan ninu ilana naa tabi simẹnti epo-eti ti o sọnu jẹ:

- Ṣẹda apẹrẹ epo-eti tabi ẹda-ara

- • Sprue ilana epo-eti

- • Nawo ilana epo-eti

- • Yọọ ilana epo-eti kuro nipa sisun rẹ (inu ileru tabi ninu omi gbona) lati ṣẹda apẹrẹ kan.

- • Fi agbara mu irin didà sinu m

- • Itutu ati Solidification

- Yọ sprue kuro ninu awọn simẹnti

- • Pari ati didan awọn simẹnti idoko-owo ti o pari

Itọju Ooru ti AISI 316 Awọn Simẹnti Irin Alagbara:

Ooru si 1900°F (1040°C) o kere ju, dani fun akoko ti o to, pa ninu omi tabi tutu ni iyara nipasẹ awọn ọna miiran. AISI 316 dọgba si CF8M/F316 ati Kannada Standard 0Cr17Ni12Mo2. AISI 314 jẹ iyipada ti o nru molybdenum ti AISI 304 alloy ati pe o jẹ simẹnti deede ti irin alagbara CF8M ti a ṣe. Iwaju molybdenum ṣe alekun resistance ipata gbogbogbo ati resistance si pitting nipasẹ awọn chlorides. A lo alloy ni awọn ipo ekikan kekere ati ipilẹ ati fun mimu citric, oxalic ati phosphoric acids.