Aṣa ile àtọwọdá ti ile oloke meji alagbara, irin yi nipa idoko simẹnti lati China simẹnti Foundry pẹluẹrọ, itọju ooru, ati awọn iṣẹ itọju oju.

RMC simẹntikonge simẹnti irin awọn ẹya arati o pade nigbagbogbo tabi kọja awọn ireti alabara. Simẹnti idoko epo-eti ti o padanu gba wa laaye lati gbejadeirin alagbara, irin simẹnti awọn ọjabi kekere bi mewa ti giramu ati bi o tobi bi mewa ti kilo, ni kan jakejado ibiti o ti ferrous ati ti kii-ferrous alloys ati pẹlu exceptional onisẹpo deede.

Ilana simẹnti idoko-owo epo-eti ti o padanu n ṣe awọn simẹnti pipe-apẹrẹ ti o sunmọ-net ti o nigbagbogbo nilo diẹ tabi ko si afikun ẹrọ. Ipari Abajade tun dara pupọ ju ohun ti o ṣee ṣe nipasẹ simẹnti miiran tabi awọn ilana iṣelọpọ. Agbara ati agbara ti awọn ẹya simẹnti jẹ ki ara wọn jẹ apẹrẹ fun awọn ohun elo ti o ga julọ-resistance to nilo awọn miliọnu awọn iyipo.

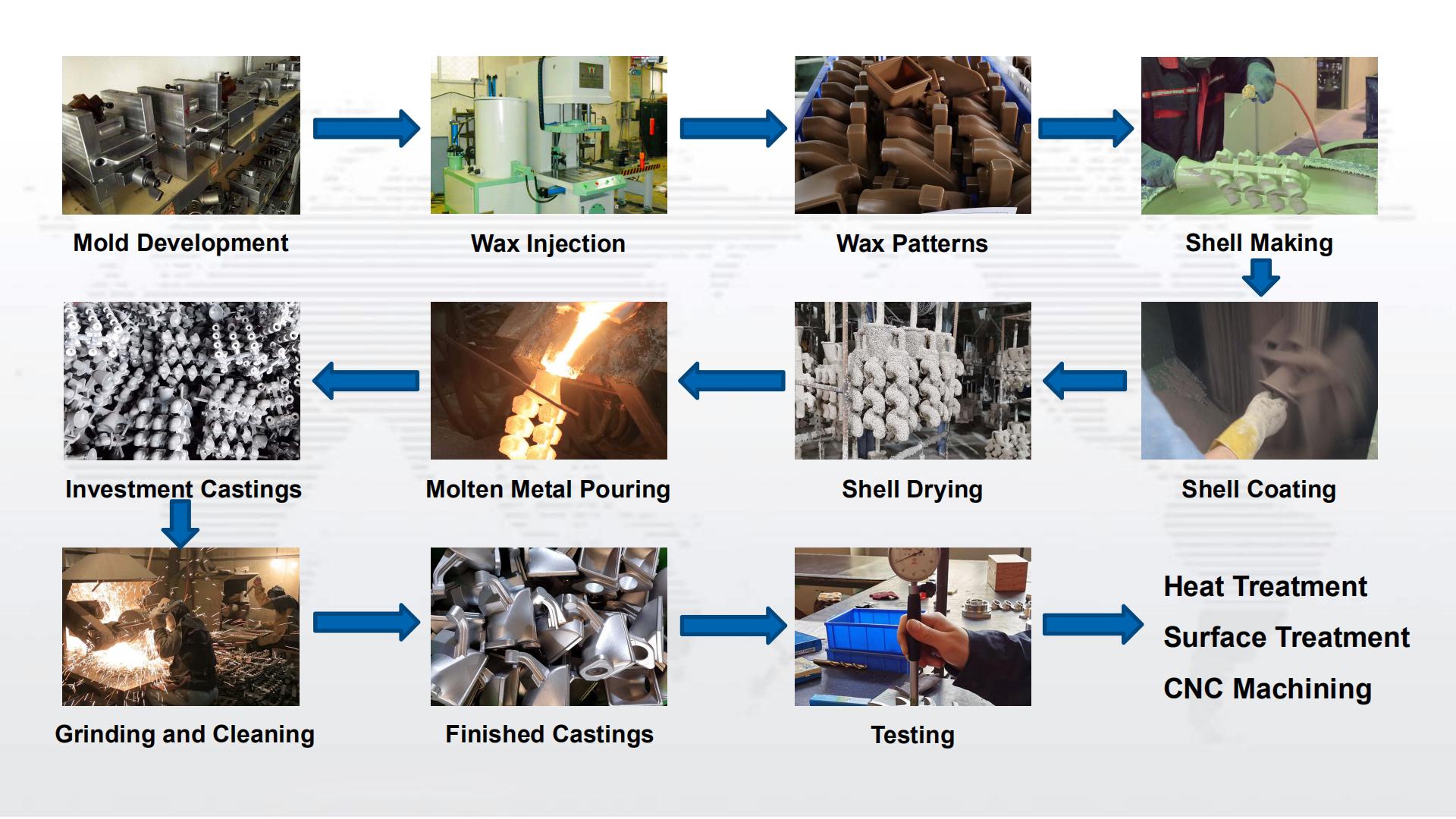

Awọn Igbesẹ ti Ilana Simẹnti Idoko-owo:

Lakoko ilana simẹnti idoko-owo, ilana epo-eti ti wa ni bo pẹlu ohun elo seramiki, eyiti, nigbati o ba di lile, gba geometry inu ti simẹnti ti o fẹ. Ni ọpọlọpọ igba, awọn ẹya pupọ ni a sọ papọ fun ṣiṣe giga nipasẹ sisopọ awọn ilana epo-eti kọọkan si ọpá epo-eti aarin ti a pe ni sprue. Awọn epo-eti ti wa ni yo kuro ninu apẹrẹ - eyiti o jẹ idi ti a tun mọ ni ilana ilana epo-eti ti o padanu - ati irin didà ti a dà sinu iho. Nigbati irin naa ba di mimọ, mimu seramiki naa ti mì, nlọ apẹrẹ apapọ ti o sunmọ ti simẹnti ti o fẹ, atẹle nipa ipari, idanwo ati apoti.

Irin Alagbara Duplex (DSS) tọka si irin alagbara, irin pẹlu ferrite ati austenite iṣiro kọọkan fun iwọn 50%. Ni gbogbogbo, akoonu ti awọn ipele ti o kere si nilo lati jẹ o kere ju 30%. Ninu ọran ti akoonu C kekere, akoonu Cr jẹ 18% si 28%, ati akoonu Ni jẹ 3% si 10%. Diẹ ninu awọn irin alagbara duplex tun ni awọn eroja alloying gẹgẹbi Mo, Cu, Nb, Ti, ati N.

Ipele ti o wa ti irin alagbara irin duplex ni RMC Simẹnti Foundry: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890 3A 5A 9A 8A 995 1B, A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

DSS naa ni awọn abuda ti austenitic ati irin alagbara ferritic. Akawe pẹlu ferrite, o ni o ni ti o ga plasticity ati ductility, ko si yara otutu brittleness, ati significantly dara si intergranular ipata resistance ati alurinmorin išẹ, nigba ti ṣi mimu brittleness, ga gbona iba ina elekitiriki, ati superplasticity bi ferrite alagbara, irin. Ti a ṣe afiwe pẹlu irin alagbara austenitic, DSS ni agbara giga ati ilọsiwaju ilọsiwaju pataki si ipata intergranular ati ipata wahala kiloraidi. Irin alagbara Duplex ni o ni o tayọ pitting ipata resistance ati ki o jẹ tun nickel-fifipamọ awọn alagbara, irin.

| Ite deede ti Irin Alagbara | |||||||

| EGBE | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic ati Ferritic Irin Alagbara | 420 C | 1.4034 | X43Cr16 | ||||

| 440 B/1 | 1.4112 | X90 cr Mo V18 | |||||

| - | 1.2083 | X42 cr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 cr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | X12 CrS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 cr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 cr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Austenitic Irin Alagbara | 304 | 1.4301 | X5 KrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 KrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 KrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Ile oloke meji Irin alagbara | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

▶ Awọn irin irin ati Awọn irin ti kii ṣe irin funSimẹnti idoko-owo, Ilana Simẹnti epo-eti ti sọnu:

• Irin grẹy: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Irin Ductile tabi Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Erogba Irin: AISI 1020 - AISI 1060, C30, C40, C45.

• Irin Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo ... ati be be lo lori ìbéèrè.

• Irin alagbara: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 ati awọn miiran alagbara, irin ite.

• Brass, Red Copper, Bronze tabi awọn irin alloy ti o da lori Ejò: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Awọn ohun elo miiran gẹgẹbi awọn ibeere alailẹgbẹ rẹ tabi ni ibamu si ASTM, SAE, AISI, ACI, DIN, EN, ISO, ati awọn ajohunše GB

▶ Awọn agbara tiIdoko Simẹnti Foundry

• Iwọn ti o pọju: 1,000 mm × 800 mm × 500 mm

• Iwọn Iwọn: 0,5 kg - 100 kg

• Agbara Ọdọọdun: 2,000 toonu

• Awọn ohun elo iwe adehun fun Ilé Ikarahun: Silica Sol, Gilasi Omi ati awọn apopọ wọn.

| Awọn iṣẹ | Apejuwe |

| Dada Itọju Services | Aso lulú, Anodization, Electrophotesis, Chrome Plating, Painting, Iyanrin bugbamu, Nickel Plating, Zinc Plating, Blacking, Polishing, Bluing, Geormet, Zintek, etc. |

| CNC konge Machining Services | Lilọ, Milling, Titan, Honing, Liluho, Alaidun, Fọwọ ba, Wire Electrode Ige, Lilọ ... ati be be lo. |

| Ayewo ati Didara Iṣakoso | Spectrum Analyzer, CMM, Onidanwo Lile, Oludanwo Agbara Fifẹ, Yild Strentgh Testor, Oluyẹwo Ipa Titẹ, Oluyanju Efin Efin Erogba, Maikirosikopi Metallurgical, Tester Force Tester...ati be be lo. |